-

Our Products

- Unsupported Films – Flexible Packaging

- Unsupported Films – Prime Labels

- Photofinishing Solutions

- Essentials Collection

- Tactile Collection

- Endurance Collection

- Sustainable Collection

- Holographic Collection

- Metalized Collection

- Sleeking® Collection

- Educational Collection

- Presentation Collection

- Laminating Equipment

- Material Handling Equipment

-

Product Description

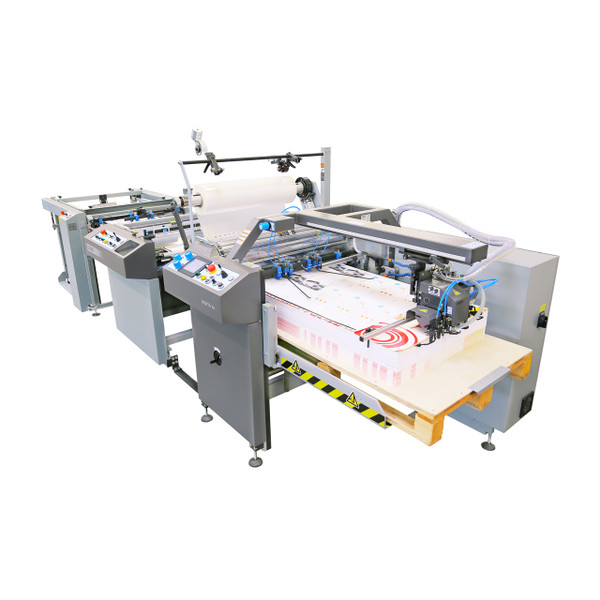

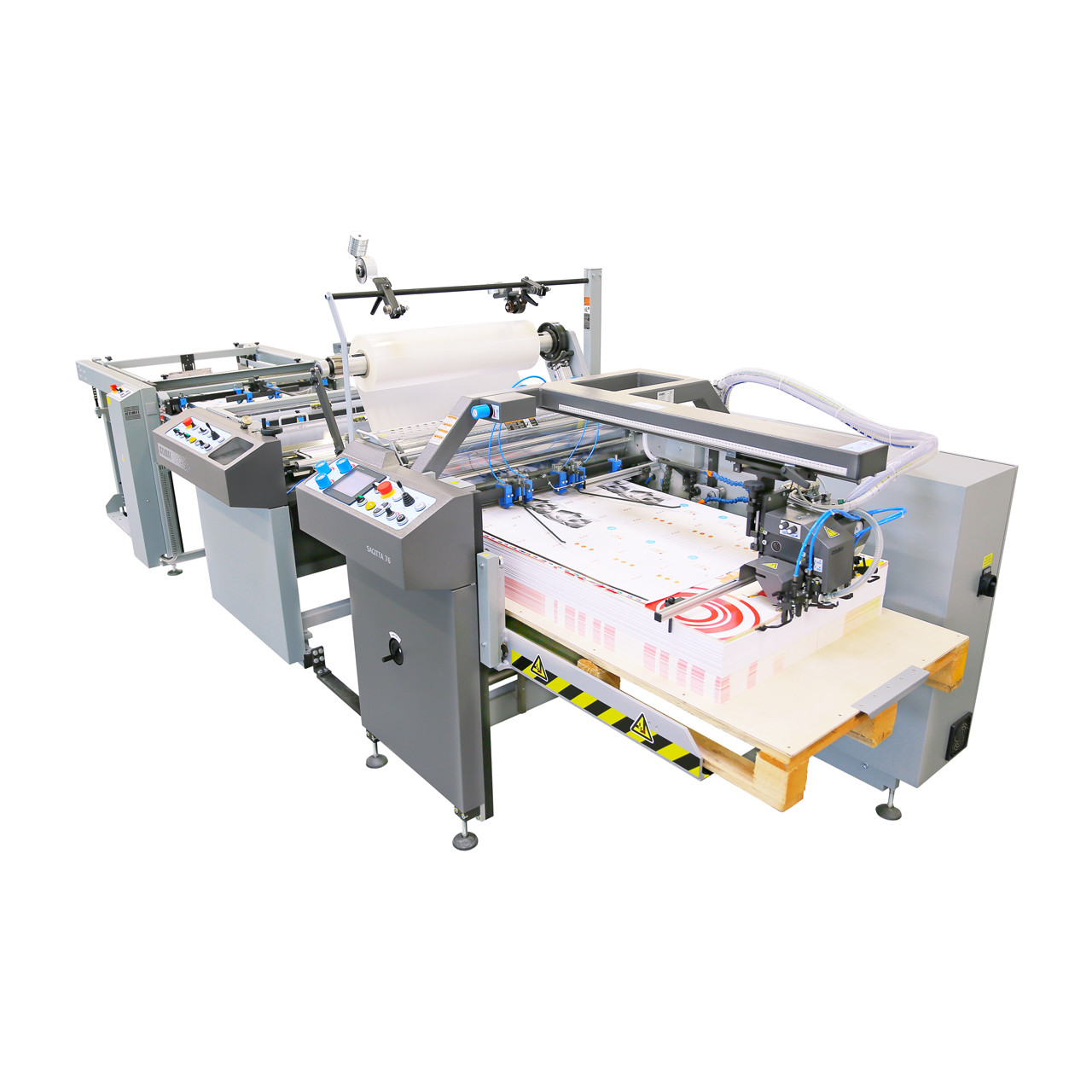

A TOP-FEED LAMINATOR FOR EFFICIENT SINGLE-SIDED LAMINATION

The Komfi® Sagitta 76 is a high-production, high-volume, single-sided thermal laminator with a specially designed dual-action automatic Komfi feed head. Sheets are taken from a pallet using a combination of vacuum power and long sheet separation air blowers. Automated sheet overlap control ensures smooth, flawless operation. Mis-feeding and temperature drop detection help prevent malfunctions mid-run. This unit accepts a maximum sheet size of 29.9" x 44".

A three-zone electrical resistance heating system warms the laminating cylinder to provide accurate, even heat throughout the lamination process. The polyurethane-coated pressure roller ensures a proper bond forms between the thermal laminate and the substrate. To support high-volume runs, this unit employs a built-in perforator, rotating knives or a hot knife, and a speed-adjustable separating roll for efficiency post-lamination.

Optional features include an on-roll film slitter, antistatic bar, and an additional in-line perforator. A film roll lift can be purchased with the ability to lift 176 lbs. (80 kg). Instead of a jogger, this unit can be shipped with an B1-sized automatic stacker. An OTF module for Sleeking® and a kit for running window lamination or substrates 18 pt. and above are also available.

STANDARD FEATURES

• Automatic feeder - feeding from pallet

• Specially designed Komfi feed head

• Maximum sheet size: 29.9" x 44"

• Long sheet separation air blowers

• Automatic sheet overlap control

• Mis-feeding detection

• Laminating cylinder heated by 3-zone electrical resistance heater

• Temperature drop detection

• Polyurethane-coated pressure roll

• Air pressure decrease detector

• Airshaft for film unwinding

• Adjustable sheet de-curling unit

• Automatic sheet separation using rotating knives and built-in perforator or hot knife

• Snapping unit is pneumatically controlled

• Speed adjustable snapping roller

• Sheet separation detector

• Jogging table

• Spare parts kitOPTIONAL FEATURES

• High-pile option

• On-roll film slitter

• Additional on-roll perforator (not recommended for hot knife model)

• Film roll lift 80 kgs

• Antistatic bar

• B1-sized automatic stacker

• Windows lamination/thicker board kit

• Stand-alone OTF module for Sleeking® -

Warranty Information

-

Find Similar Products by Category

Download Spec Sheet

Download Spec Sheet