-

Our Products

- Flexible Packaging Solutions

- Prime Label Solutions

- Photofinishing Solutions - Digital Photopaper

- Sustainable Solutions

- Foundations Collection

- Essentials Collection

- Tactile Collection

- Endurance Collection

- Holographic Collection

- Metalized Collection

- Sleeking® Collection

- Educational Collection

- Presentation Collection

- Thermal Lamination Machines

- Material Handling Equipment

-

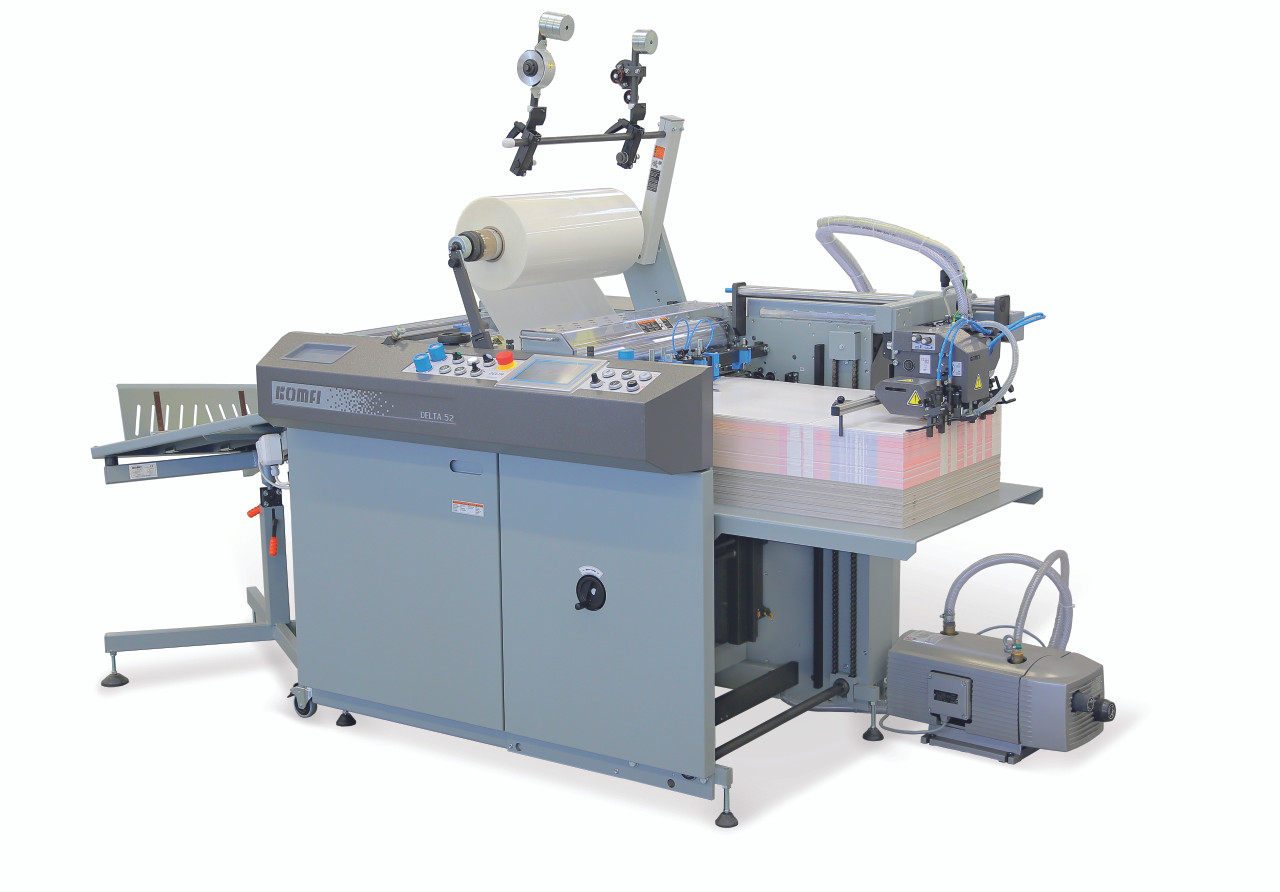

Product Description

A TOP-FED, SINGLE-SIDED LAMINATOR FOR HIGH-VOLUME RUNS

The Komfi® Delta 52 is a single-sided production laminator that can be used for photobooks, packaging applications, publications, and more in both digital and offset setups. This unit features burst separation and an automatic, specially designed Komfi top feed head that allows operators to place large stacks of sheets at once. Sheet overlap control is also automated, and mis-feed detection, a vacuum pump, and an air-pressure decrease detector help ensure each run is smooth from start to finish. This unit accepts a maximum sheet size of 22" x 31".

The Komfi Delta 52 features a laminating cylinder that is heated by a two-zone electro-resistance heater. A temperature pressure roller presses down on laminates as they are applied to subtrates to create a strong, consistent bond, and an air shaft makes changing rolls of film quick and easy. Operators can program job settings into the control panel to enable repeat or similar runs with minimal effort. As one of the safest laminators on the market, this unit can be operated by team members of all skill levels.

Best suited for running BOPP thermal laminates, the Komfi Delta 52 employs a built-in perforator for automatic sheet separation, and its bar-and-roller de-curling unit keeps finished pieces from bowing or curling. Optional features include an on-roll film slitter, additional separation air blowers, a film roll lift, and an antistatic bar.

STANDARD FEATURES

• Single-sided lamination

• Automatic Komfi feed head

• Burst separation

• Best for BOPP thermal laminates

• Maximum sheet size: 22" x 31"

• Heavy-duty modular design

• Air shaft included for film mandrel

• De-curling bar

• Spare parts kitOPTIONAL FEATURES

• On-roll film slitter

• Additional separation blowers

• Long sheet separation blowers

• Additional on-roll perforator

• Vibrating knives

• Antistatic bar

• Automatic stacker or jogging table

• Film roll lift -

Warranty Information

-

Find Similar Products by Category

Download Spec Sheet

Download Spec Sheet