-

Our Products

- Flexible Packaging Solutions

- Prime Label Solutions

- Photofinishing Solutions - Digital Photopaper

- Sustainable Solutions

- Foundations Collection

- Essentials Collection

- Tactile Collection

- Endurance Collection

- Holographic Collection

- Metalized Collection

- Sleeking® Collection

- Educational Collection

- Presentation Collection

- Thermal Laminators

- Material Handling Equipment

-

Product Description

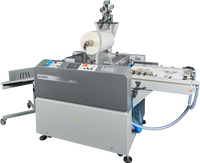

AN AUTOMATIC TOP-FED LAMINATOR FOR LONG, SINGLE-SIDED RUNS

The Komfi® Amiga 52 Top Feeder is a single-sided thermal laminator designed for production-volume digital and offset projects. This unit features an automatic, specially designed Komfi top feed head and can be ordered with either burst separation only or a combination of hot knife and burst separation. Sheet-overlap control, nip pressure activation, and sheet separation are also automated. A de-curling bar ensures each laminated piece performs as intended.

The Amiga 52 Top Feeder supports efficient, user-friendly operation with its highly accessible control center, which features a range of programmable settings, including preset job parameters for similar projects. Mis-feeding and temperature-drop detection ensures each run is completed smoothly and without error. When a run is stopped midway through, the unit preserves the position of sheets mid-feed by releasing suction only after the sheet is lowered. This keeps gaps from forming between sheets when the run begins once again. Able to detect how many sheets remain in the feeder, this unit adjusts run speed according to laminate roll volume.

Ideal for brochures, direct mail, and greeting cards, the Amiga 52 can also be ordered with a variety of optional features, including an automatic stacker or jogging table, film loading equipment, and an on-roll film perforator. A PTFE-coated or polyurethane pressure roller can also be added at request.

For short-run volumes, see the Komfi® Amiga 52 Bottom Feeder.

STANDARD FEATURES

• Single-sided lamination

• Digital and offset output

• Automatic operation

• Burst separation (BOPP) or hot knife and burst separation (BOPP, PET, and Nylon)

• Maximum sheet size: 22" x 31"

• Centralized control panel

• De-curling bar

• Spare parts kitOPTIONAL FEATURES

• Automatic stacker or jogging table

• Polyurethane or PTFE-coated pressure roller

• On-roll film perforator

• Air shaft for film mandrel

• Antistatic options

• Film loading equipment

• On-roll film slitter

• OTF module for Sleeking® -

Warranty Information

-

Find Similar Products by Category

Download Spec Sheet

Download Spec Sheet