-

Our Products

- Flexible Packaging Solutions

- Prime Label Solutions

- Photofinishing Solutions - Digital Photopaper

- Sustainable Solutions

- Foundations Collection

- Essentials Collection

- Tactile Collection

- Endurance Collection

- Holographic Collection

- Metalized Collection

- Sleeking® Collection

- Educational Collection

- Presentation Collection

- Thermal Lamination Machines

- Material Handling Equipment

-

Product Description

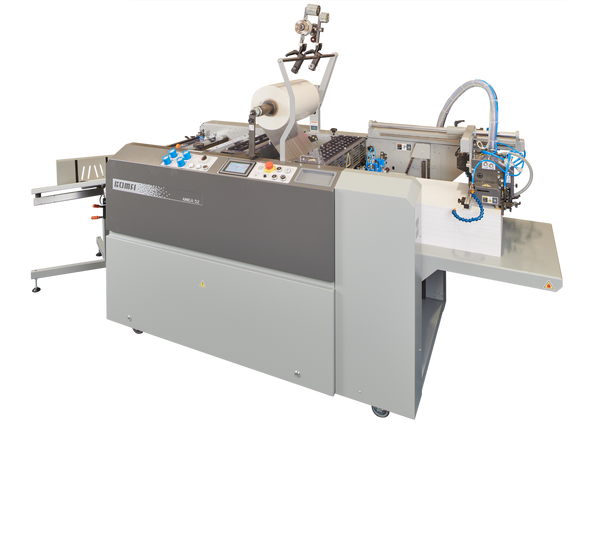

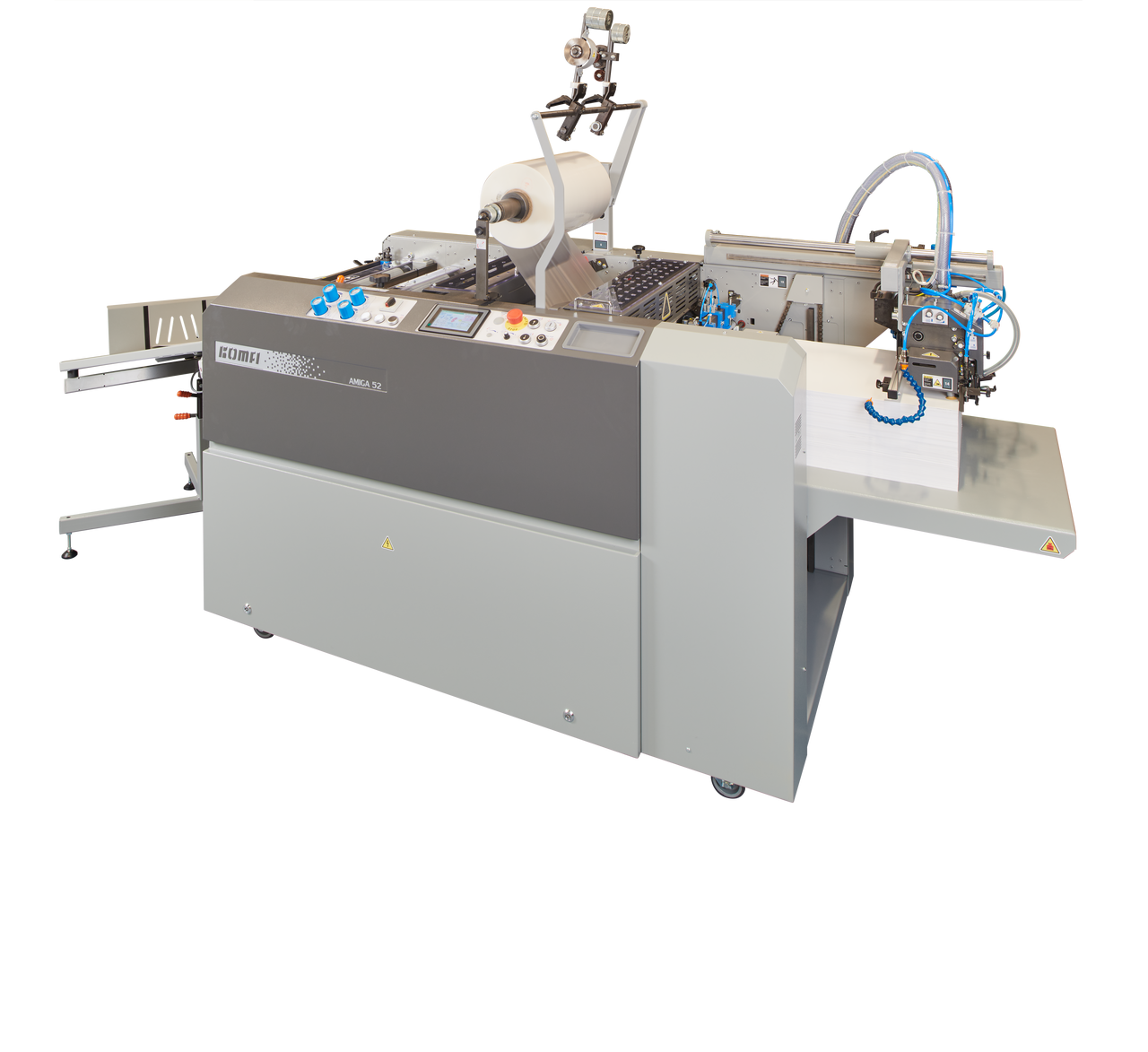

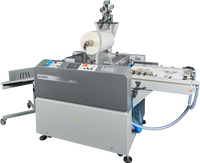

AN AUTOMATIC PRODUCTION UNIT THAT PERFORMS IN-LINE EMBOSSING

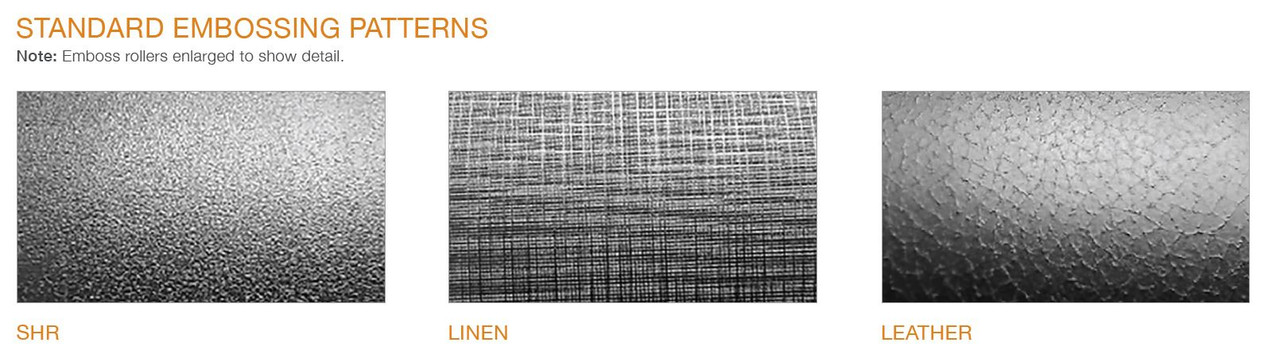

The Komfi® Amiga 52 Emboss is a thermal laminator that accepts both digital and offset output for single-sided lamination. This production laminating system features a chilled, laser-etched embossing roller to enable in-line embossing. Available patterns include leather, linen, and SHR™, which gives digital photographs the look and feel of traditional silver halide photos. The roller can be engaged or disengaged as needed mid-production. A Komfi deep-pile top feed head allows operators to set down large stacks of sheets at once.The Amiga 52 Emboss has several features that support efficiency and automation, such as automated nip pressure activation, sheet-overlap control, and bursting sheet separation. Temperature-drop and mis-feeding detection, a built-in de-curling unit, and a highly accessible control center with programmable settings help ensure each finished sheet is of the highest quality. This unit preserves the position of sheets mid-feed when a run is unexpectedly stopped by releasing suction only after the sheet is lowered. This feature prevents gaps from forming between sheets when the unit is started again. Able to adjust its run speed based on how much film remains on the roll, this unit can also detect how many sheets remain in the feeder.Excellent for laminating and embossing digital photographs, book covers, business cards, and more, the Amiga 52 Emboss is also available with a host of optional features, such as a jogging table, automatic stacker, and a film slitter for the laminate roll. Printers can further enhance their prints by ordering custom embossing roller patterns or a Sleeking® attachment for on-demand variable-data foiling.For a laminator without an embossing roller, see the Komfi® Amiga 52 - Top Feeder or the Komfi® Amiga 52 - Bottom Feeder.STANDARD FEATURES• Embossing roller for in-line embellishment (chiller included)

• Single-sided lamination

• Digital and offset output

• Deep-pile top feed head

• Automatic operation

• Burst separation (BOPP, thin PET, and Nylon)

• Maximum sheet size: 22" x 31"

• Centralized control panel• De-curling bar and roller

• Polyurethane (PUR) pressure rollers

• Fixed table for unloadingOPTIONAL FEATURES• Custom embossing roller patterns

• OTF module for Sleeking

• Air shaft

• On-roll film perforator

• Automatic stacker or jogging table• Antistatic options

• On-roll film slitter

• Film loading equipment -

Warranty Information

-

Find Similar Products by Category

Download Spec Sheet

Download Spec Sheet