-

Our Products

- Flexible Packaging Solutions

- Prime Label Solutions

- Photofinishing Solutions - Digital Photopaper

- Sustainable Solutions

- Foundations Collection

- Essentials Collection

- Tactile Collection

- Endurance Collection

- Holographic Collection

- Metalized Collection

- Sleeking® Collection

- Educational Collection

- Presentation Collection

- Thermal Lamination Machines

- Material Handling Equipment

-

Product Description

A GRITTY, TEXTURED LAMINATE FILM

FineGrit™ Laminate is a rugged, textured laminate film that gives printed pieces the feel of fine-grain sandpaper. Its rough-touch appeal offers brands a contrast with popular soft-touch trends in general commercial print to help brands target different demographics and markets. Highly scuff resistant, its stippled, gritty surface is cured and has no loose particles that can be rubbed off, making it perfect for any application that will be reused or handled frequently. Add FineGrit to folding cartons to create unforgettable tactile packaging that instantly stands out when picked up in a retail store. Apply it to business cards to convey toughness and grit to prospective clients. Ensure board game pieces do not scuff or scratch despite years of repeated use. This laminate can even be used to elevate digitally printed stand-up pouches, stick packs, and other types of flexible packaging. With FineGrit textured laminate film, the print enhancement possibilities are nearly endless.

FineGrit textured laminate film is part of the Nobelus® Tactile Collection.

SPECIFICATIONS

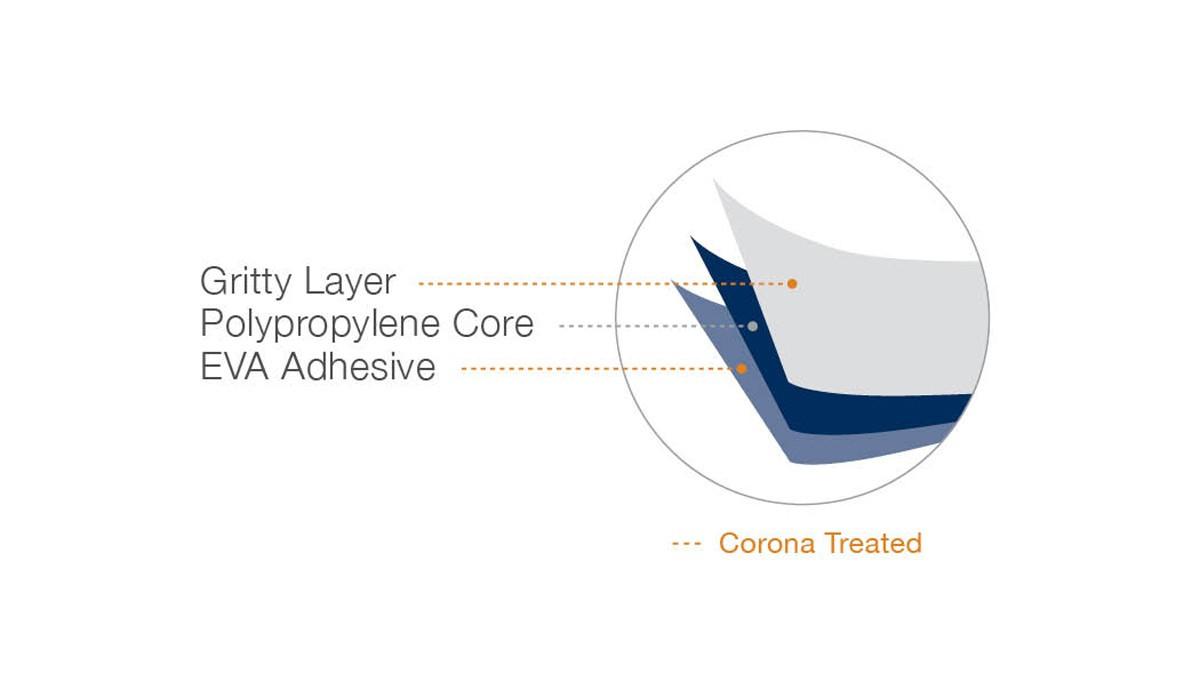

BOPP | 2.0 mil | EVA Adhesive | Compatible with offset, flexographic, and HP® Indigo ink

KEY FEATURES

• Light, sandy texture gives prints a rugged feel

• Durable finish will not scuff off

• Superb color tonality

• Clear topcoat ensures designs show through clearlyWHAT APPLICATIONS ARE BEST FOR FINEGRIT TEXTURED LAMINATE FILM?

• Board Games

• Folding Cartons

• Loyalty and Gift Cards

• Pocket Folders

• Postcards and Direct Mail

• Rigid Boxes

• Sachets

• Soft and Hardbound Book Covers

• Stand-Up Pouches

• Stationery and Greeting Cards

• Three-Sided Sealed BagsIS FINEGRIT LAMINATE COMPATIBLE WITH POST-LAMINATE PROCESSES?

• Die Cutting*

• Folding

• Gluing*

• Printing - Offset, UV, and Screen*

• Spot Varnish and UV*

• Stamping*WHAT MARKETS USE FINEGRIT LAMINATE?

• Cannabis

• Collateral

• Collectible Cards

• Electronics

• Health and Beauty

• Luxury Goods

• Nutraceuticals

• Pet Products

• Print On Demand and Publications

• School Supplies*Uneven surface may affect receptiveness to certain processes. Testing is required. A minimum 12 g/m2 coating is required to cover the textured surface.

-

Warranty Information

-

Find Similar Products by Category

Download Spec Sheet

Download Spec Sheet