-

Our Products

- Unsupported Films – Flexible Packaging

- Unsupported Films – Prime Labels

- Photofinishing Solutions

- Essentials Collection

- Tactile Collection

- Endurance Collection

- Sustainable Collection

- Holographic Collection

- Metalized Collection

- Sleeking® Collection

- Educational Collection

- Presentation Collection

- Laminating Equipment

- Material Handling Equipment

-

Product Description

HIGH-EFFICIENCY LAMINATOR FOR MAXIMIZED PRODUCTIVITY

The Komfii® Sirius 110 is specially designed for high-volume, high-speed runs of B1 sheets, making it an ideal unit for folding cartons, rigid boxes, book covers, and many other applications. This machine is also capable of producing metalized board stock, enabling printers to move the process in-house to reduce lead times, material waste, and sourcing costs.

Its high-pile pallet-in/pallet-out system enables it to hold stacks of sheets as high as 53 inches (including the pallet). Because this system includes features like automatic sheet overlap control and sheet separation, operators can leave sheets in the feeder and focus on other tasks while the laminator processes the stack.

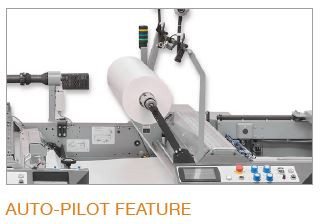

The Sirius 110 has a high-capacity unwind shaft that maximizes throughput by accepting large film rolls up to 20,000 feet long depending on the thickness of the laminate. An auto-pilot feature detects when laminate is running low on the film roll and alerts operators to ensure more seamless changeovers.

This large laminating system is engineered with a catwalk that spans across the length of the machine to give operators full access to different components for maintenance, repairs, cleaning, and regular setup. It features front-load and side-load accessibility with fold-up stairs to save space on the production floor and limit access to the machine as needed.

Optional features include a reinforced and extended film roll lift for faster and safer changeovers, an on-roll film slitter, an IR preheater, and anti-static options.

STANDARD FEATURES

• High-speed lamination for large volumes

• Integrated catwalk provides operators with safe access

• Processes B1 sheets for various applications

• High-pile pallet-in/pallet-out system

• Deep-pile top feed head

• Auto-pilot feature detects when laminate roll is low

• High-capacity unwind shaft for large film rolls (up to 20,000 feet on a 3" core with 1 mil laminate)

• Pressure roller is coated in polyurethane

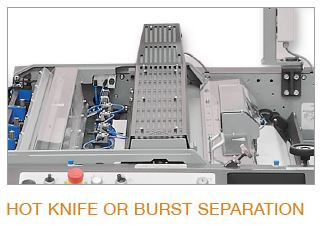

• Hot knife separation compatible with BOPP, PET, cellulose and nylon laminates

• Spare parts kit included

• Laminates 80 lb text - 32 pt board

• Chrome roller with three-zone electrical heating system for maximum laminating pressure

• Enables in-house metalized board stock productionOPTIONAL FEATURES

• Reinforced and extended film roll lift

• On-roll film slitter

• Add-on perforator

• Anti-static optionsCOMMON APPLICATIONS

• Brochures

• Folding Cartons

• Metalized Board

• Point of Sale

• Postcards and Direct Mail

• Rigid Boxes

• Soft and Hardbound Book Covers -

Warranty Information

-

Find Similar Products by Category

Download Spec Sheet

Download Spec Sheet